Since the acquisition of COPEX by the LEFORT® Group in the summer of 2023, the Breton manufacturer has integrated the KOLOSS into its range of static shears with press wings.

KOLOSS heavy-duty scrap shears are ideal for compacting and cutting very large volumes of a variety of light to medium-heavy scrap metal.

With cutting forces ranging from 1,000 to 1,700 tonnes, they ensure high compaction performance through their wrap-around compression box and press wings, and very high cutting speed.

These multi-bloc machines are divided into 3 major subassemblies/parts: .

- the extremely robust shear head ensuring fast cutting process,

- the compression box perfectly suitable for intensive use,

- and the power pack providing great operating flexibility and high energy efficiency.

The KOLOSS are very easy to install using simple and cost-effective civil engineering.

Supplied as standard with a remote control with a large control screen, they can also be delivered with a safety platform and cabin for safe and comfortable operation.

Key Advantages

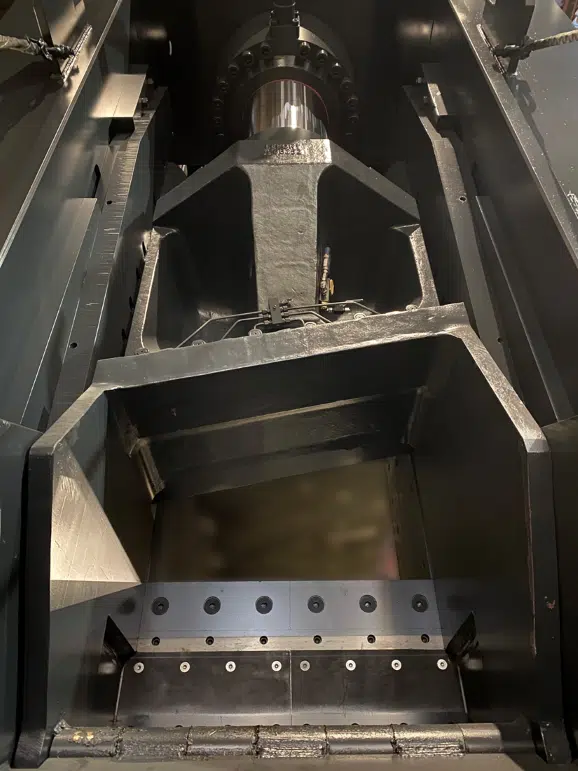

Shear Head: Built to Last

One of the key components of the KOLOSSs is the shear head, an entirely fabricated unit. Its specific features make it particularly robust and efficient: automatic centralized lubrication, hydraulic blade fixing system for rapid blade change.

A special feature patented by LEFORT®: the hold-down with “combs”, which reduces wear and the risk of scrap metal jamming.

A Robust and Efficient Compression Box

Particularly suitable for intensive use, KOLOSS machines have a compression box with the whole inner structure equipped with wear plates of a hardness of +/- 450 HB and a thickness of up to 12 mm. The wear plates on the bottom and both sides of the compression box are easily replaceable. The box hinges as well as the side-mounted hydraulic cylinders and all articulation points, are equipped with an automatic lubrication system. Box hinges are made of high-strength steel for durability and optimum protection when lids are closed. The compression lids have a highly efficient wrap-around function reinforced by the overstroke function. The longitudinal pusher, which can be fitted with tunnel, has a pressing force of 180 tonnes for highest densification of scrap materials. The position of the pusher is controlled using a laser system. The KOLOSS can be supplied with a hydraulic loading hopper as an option to increase production capacity.

Operational smoothness & Energy Efficiency

The power unit and the hydraulic system are configured to optimize performance while guaranteeing operating smoothness.

High cutting speeds are made possible by the simultaneous automatic execution of several movements. Speed is increased by oil transfer

in the cylinders and the use of new-generation high-pressure pumps. While cycle times are reduced, energy consumption has been cut by 17% compared with previous generations of shear balers. The proportional design of the hydraulic pumps means increased energy efficiency during certain operating phases.

New WEB VISU system

KOLOSS machines are fitted as standard with the new WEB VISU remote maintenance system developed by LEFORT®. Working with any digital device – PC, tablet, mobile phone – this system enables precise production data to be collected, and the machine to be monitored and serviced in real time, optimizing operation and maintenance.

Technical Features

| KOLOSS 1000 | KOLOSS 1300 | KOLOSS 1450 | KOLOSS 1700 | |

|---|---|---|---|---|

Cutting force | 1000 t | 1300 t | 1450 t | 1700 t |

Cutting width | 960 mm | 960 mm | 1140 mm | 1360 mm |

Hold-down force | 240 t | 300 t | 400 t | 400 t |

Compression box | 8000 x 2800 mm | 8000 x 2800 mm | 8000 x 3140 mm | 8000 x 4200 mm |

Wings force | 2 x 400 t | 2 x 400 t | 2 x 450 t | 2 x 600 t |

Electrical power | 1 x 315 kW | 5 x 110 kW | 5 x 110 kW | 6 x 110 kW |

Diesel drive | 1 x 600 hp | 2 x 600 hp | 2 x 600 hp | Consult Us |

Gallery