PCV shearing ram balers are used to compact scrap metal and metal scrap into high-density bales.

Allowing continuous feed by grapple or conveyor, they are particularly suitable for the processing of continuous flow products, such as in the automotive industry or industrial cutting.

Fully automatic, they provide an optimal response to the requirements of industry professionals, and are also used by scrap and metal recyclers. They can be installed outdoors or indoors and do not require any special civil engineering.

Specific advantages of the shearing ram : Optimal bale quality

- The PCV balers allow a continuous loading of the materials during the compaction cycle, and thus are perfectly suited for use in an industrial environment,

- In the case of heterogeneous materials, the blades cut off any protruding products during the first horizontal compression,

- The system for adjusting the clearance between the blades guarantees perfect shearing and the quality of the finished bales.

Key Advanttages

COPEX offers a wide range of shearing ram balers which are characterized by their high performance and very long service life. They can meet all operating needs:

- Processing of all types of ferrous and non-ferrous scrap: metal scrap (copper, aluminium, zinc, steel, stainless steel, etc.), household metal waste from selective collection, light scrap, etc.,

- Presses especially designed for industrial use,

- Solidity and reliability thanks to a robust welded construction,

- Continuous press feeding,

- Very high material densification,

- Feeding hopper adapted to the different products to be treated and to the operating mode,

- Adjustable mechanical stops on the compression pistons for precise guidance during compaction phases,

- Optimal protection of the compression cylinders by mechanical locking,

- Ease of installation without special civil engineering, meeting the space constraints of industrialists,

- Grooved wear plates when required by the materials to be compacted to avoid any risk of jamming,

- Operational safety,

- Low noise level,

- Efficient hydraulics and high production outputs due to simultaneous movement execution,

- Fully automatic operation,

- Complete lines including complementary equipment such as conveyors, weighing hoppers, etc…,

- Intuitive touch screen HMI interface for access to production parameters and operating data: Adjustable bale length, final pressure and density,

- Optimization of maintenance operations thanks to touch screen controls,

- Remote maintenance via modem,

- Reduced operating costs thanks to long and reliable guides.

Technical Features

| Model | P1CV 4030 | P1CV 5030 | P2CV 3030 | P2CV 4040 | P2CV 6060 | P3CV 3030 | P3CV 4040 | P3CV 6060 |

| Bale section | 400 x 300 mm | 500 x 300 mm | 300 x 300 mm | 400 x 400 mm | 600 x 600 mm | 300 x 300 mm | 400 x 400 mm | 600 x 600 mm |

| Feed opening | 1000 x 360 mm | 1040 x 460 mm | 2000 x 1120 mm | 2500 x 1720 mm | 2700 x 1920 mm | 1900 x 1190 mm | 2000 x 1430 mm | 5000 x 1930 mm |

| Final compression | 63 t | 80 t | 120 t | 250 t | 320 t | 200 t | 350 t | 1000 t |

| Hourly output Aluminium | ≤ 0.7 t/h | ≤ 1 t/h | ≤ 2.2 t/h | ≤ 6 t/h | ≤ 15 t/h | ≤ 5.5 t/h | ≤ 10 t//h | ≤ 23 t/h |

| Hourly output Steel/copper | ≤ 2 t/h | ≤ 3 t/h | ≤ 6.5 t/h | ≤ 17 t/h | ≤ 42 t/h | ≤ 15 t/h | ≤ 32 t/h | ≤ 67 t/h |

| Installed power | 22 or 30 kW | 37 kW | 37 or 55 kW | 110 or 180 kW | 180 or 270 kW | 90 kW | 180 kW | 270 kW |

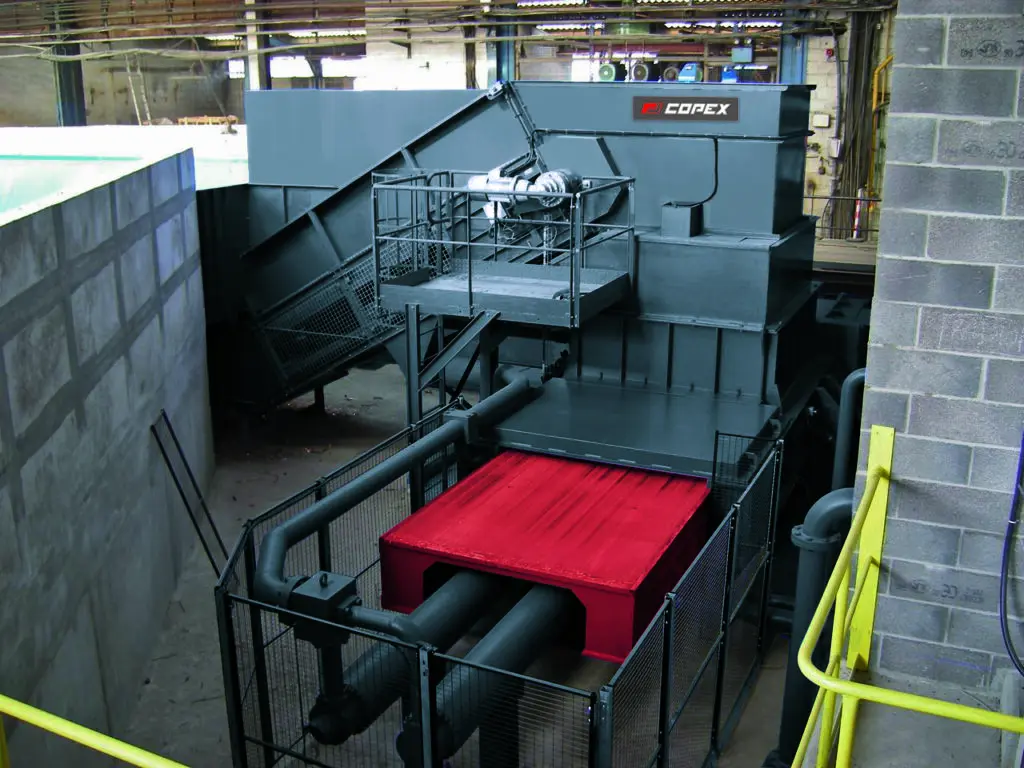

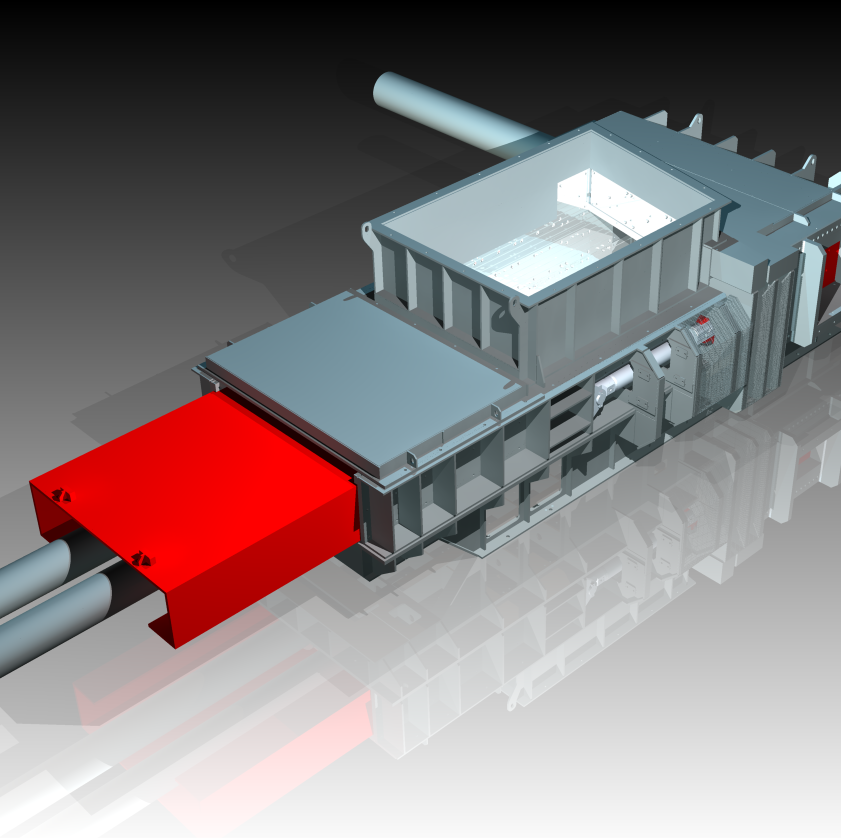

Gallery