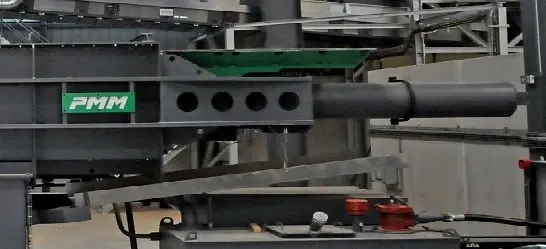

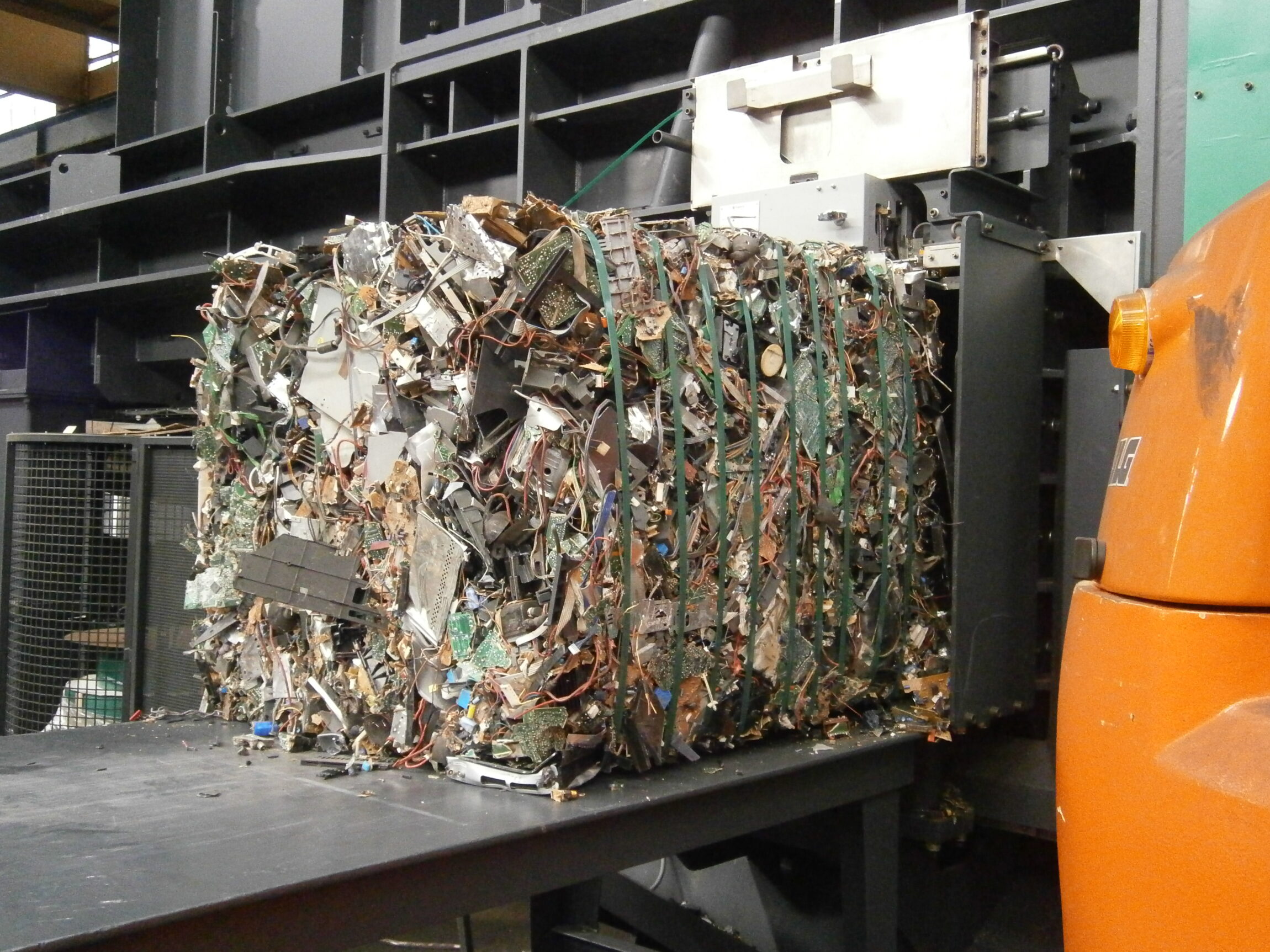

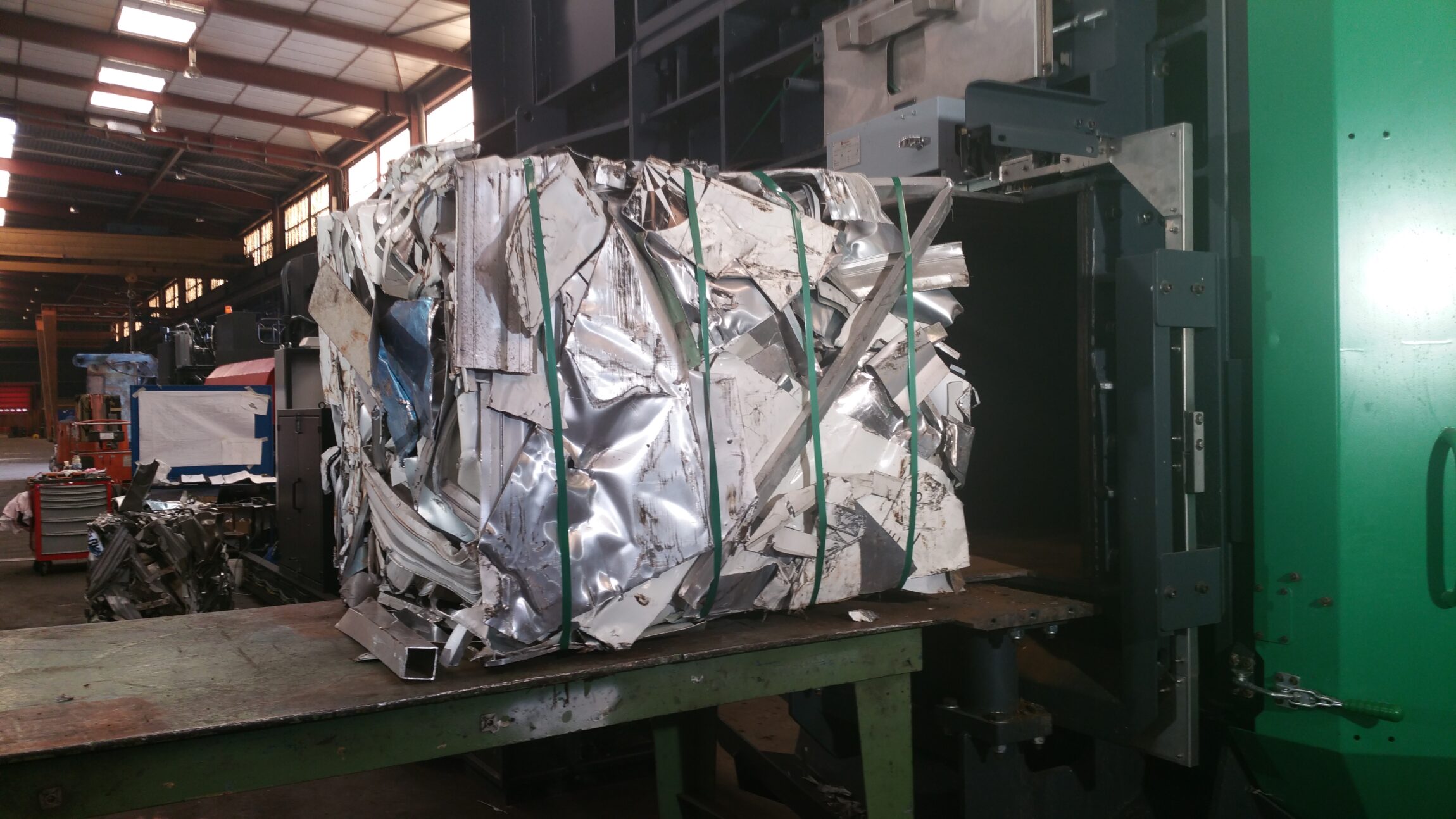

The PMM balers can bale all types of compressible materials such as household waste and residual household waste, C&I, RDF/SRF, agricultural fibres, fuelwood, WEEE, industrial steel profiles and scrap, plastics…

In response to the increasing diversification of the materials to be processed and the development of new recycling channels, COPEX offers a new generation of balers.

This machine named PMM offers exceptional qualities in terms of:

Versatility of the treated materials, whether it is RDF, industrial waste or dehydrated alfalfa,

Density and homogeneity of the bales produced,

Productivity.

Key Advantages

PMM balers have been developed to achieve high production outputs. Their effectiveness is based on a totally innovative two-stage design. Through this design the movements of the compacting and tying/ejection are working separately from each other. The simultaneous operation of these two functions, combined with high-performance hydraulics, represents productivity gains of up to 50%.

These new compact and energy-efficient balers also reduce installation costs to a minimum. As the hydraulic system is integrated underneath the machine, a single concrete slab without any reservation and an electrical supply are all that is required.

The PMM is currently one of the most effective and reliable tools on the market.

We offer complete baling lines with the possibility to integrate the following devices:

Wrapping stations,

Metal infeed conveyors,

Storage platforms,

Trailer loaders,

Bale stackers,

Bale discharge conveyors.

Technical Features

| PMM500 | PMM800 | PMM1200 | PMM1600 | |

| Power | 55 or 110 kW | 110 or 165 kW | 220 kW | 260 kW |

| Production up to | 22 t/h | 40 t/h | 59 t/h | 73 t/h |

| Dimensions of bales | ||||

| Length | 1070 mm | 1070 mm | 1070 mm | 1400 mm |

| Width | 710 +/-40 mm | 920 +/- 40 mm | 1000 mm | 1000 mm |

| Height | 600 mm | 800 mm | 1100 mm | 1100 mm |

Gallery